*JOHN GRANZIEN **LLOYDKING

*

Leading Hand Water and Sewage Operator /

Plumber

** Water and Sewage Operator

SUMMARY

The

Esk Shire Council has recently installed a Vetiver Grass Wetlands System to

treat sewerage effluent at Toogoolawah in South East Queensland. The sewerage

treatment plant is situated on a 22-hectare site on the northern edge of town.

The

aim of this scheme was to improve water quality before the effluent discharges

to the natural wetlands. The biggest problem with the quality of the effluent

is its high nutrient loading. With the recent changes to license conditions

imposed by the Environmental Protection Agency, the existing treatment plant no

longer complies with the license and an upgrade of the plant was required.

Instead

of traditional upgrades, a new and innovative nutrient-removal technology

recently developed in Queensland by the Department of Natural Resources and Mines,

is being implemented at Toogoolawah.

The

Vetiver Grass wetlands have been constructed in rows following the contours to

allow good contact between the grass and the effluent. The Vetiver Grass takes

up the water and in particular the grass will remove the nutrients from the

water that passes through it,

As

Vetiver Grass system is very effective in removing nutrient loads, it is

expected that once the wetlands is properly established there should be no

release of sewerage effluent from the treatment plant except in times of heavy

rainfall.

COUNCIL OF THE SHIRE OF ESK

This scheme will provide a large-scale

prototype of possible sewerage treatment schemes that can be used throughout

western Queensland and other locations where there is plenty of land and where

the local government doesn�t want to pay for installing and operating high cost

solutions.

INTRODUCTION

The

Esk Shire.

The

Esk Shire is situated on the north western edge of Brisbane and covers an area of 3 946 square kilometres. However the

population of the shire is only about 14,800 people and this is scattered over

most of the shire. The shire is 125 kilometres long (running north/south) and

70 kilometres wide.

TOOGOOLAWAH

The

town of Toogoolawah is situated right in the centre of the shire. The town has

a population of approximately 1,000 persons and provides the local people with

a quiet rural lifestyle about an hour and a half drive from Brisbane.

THE

PROJECT

Toogoolawah

Sewerage Plant

The

sewerage scheme for Toogoolawah was built in 1970 and the treatment plant was

constructed as a primary sedimentation (Imhoff Tank) followed by three sewerage

ponds. The effluent from the ponds was designed to flow down into a swamp area

before it entered into the local creek. The plant construction was based on a

very simple design but it is effective. With the recent changes to license

conditions imposed by the Environmental Protection Agency (EPA) the plant no

longer complies with the license and so an upgrade of the plant was required.

The

main problem with the existing sewerage effluent was that while passing through

the three ponds the nutrients were providing an environment for the production

of high concentrations of algae thus high pH levels. Various

options were considered such as a nutrient removal plant, a sand filter or a

rock filter. These are expensive options and would require expensive ongoing

operational costs. Utilities Engineer Mr. Ralph consulted Mr. Paul Ttuong from

Veticon Consulting and it was decided to introduce a wetland system. They then

considered a Vetiver Grass wetlands system that would take up most of the

water, as well as remove nutrients and heavy metals etc. from the sewerage effluent.

VETIVER

SYSTEM

Introduction

Application

of the Vetiver System (VS) for waste water treatment is a new and innovative

nutrient removal technology recently developed in Queensland by the Department

of Natural Resources and Mines, NRM, (Truong and Hart, 2001). It is a green and

environmentally friendly wastewater treatment technology as well as a natural

recycling method. Its end-product has several uses including animal fodder and

material for organic farming.

Vetiver

Grass

VS

is based on the use of vetiver grass (Vetiveria zizanioides L.), which was

first recognised early in the 1990s for having a �super absorbent�

characteristics suitable for the treatment of wastewater and leachate generated

from landfill in Queensland (Truong and Stone, 1996). Research conducted by NRM

showed that Monto vetiver grass has a fast and very high capacity for

absorption of nutrients, particularly nitrogen and phosphorus in wastewater. In

addition it has a very high water use rate and tolerant to elevated levels of agrochemicals

and heavy metals in the effluent. As a result of these findings, presently VS

has been used successfully for these purposes in Australia, China, Thailand,

Vietnam and Senegal (Truong and Hart, 2001; Truong, 2000).

Australian

Research Results

A

demonstration site was set up at the Beelarong Community Farm at Morningside,

Brisbane to obtain quantitative data on the effect of VS in improving its

quality under field conditions and also in reducing the volume of effluent. In

this DNR and EPA funded project, VS was used to treat the discharge from a

septic system. Vetiver grass was selected after the failure of other plants

including a variety of fast growing tropical grasses and trees, and crops such

as sugar cane and banana to absorb the effluent discharge from the septic tank.

After five-month growth, vetiver was more than 2m tall and a stand of about 100

vetiver plants in an area less than 50m2 have completely dried up the effluent

discharge. Other applications are used or being trialled at Armidale, Lithgow

and Beenleigh.

Results

of MEDLI Model Simulation

For

the Toogoolawah sewage treatment plant Before any work commenced, effluent being discharged had the

following characteristic

Daily

output 350 kl

Nitrogen

concentration at 21mg/L

Phosphorus

level of 9 mg/L

The

MEDLI model simulation predicted that less than 3ha of land is needed to treat

the entire effluent output to comply with EPA licensing conditions.

However

if the effluent is pre-treated in the ponds to reduce N and P concentrations by

approximately 10% before releasing into the vetiver plots, the land area needed

would be less than 1.5ha

TREATMENT

PROCESS CHOSEN FOR TOOGOOLAWAH

Introduction

A

three-phase treatment program was adopted:

Phase

1:

Alum sludge and backwash waste water entered into sewage reticulation system.

Phase

2:

Preliminary treatment in the ponds.

Phase

3:

Main treatment by vetiver wetlands.

Phase

1. It was decided to put the backwash

waste water and sludge from two clarifiers at the water treatment plant into the

sewerage reticulation system This method has been trialled elsewhere in the

state with success. The alum reduces the amount of phosphorous in the waste

water. It has proven successful here also.

Phase

2:

Preliminary treatment of effluent in the ponds

The effluent in the three ponds is first

treated hydroponically by the vetiver pontoons, which are able to reduce N and

particularly P loading of the effluent before releasing it to the wetlands.

Floating

pontoon design: The 21 floating pontoons were designed so vetiver plants

sitting on the pontoons and the roots suspending in the effluent. The size of

each pontoon is 2.4m x 2.4m with about 300 individual plants placed on each

pontoon. The number of pontoons required will depend on the level of nutrient

load. The number of pontoons can be increased later to ensure an effective

treatment process was achieved. Maintenance program will include replacement of

dead plants, regular harvest to encourage new growth .

In

addition, vetiver is being planted at the high water level around the ponds to

further reduce the nutrient loading and also to stabilise the pond banks.

Phase 3: Main treatment Vetiver

Grass Wetlands

After

being treated hydroponically in the 3-pond system, effluent is released by

trickle irrigation to the main vetiver grass wetlands areas.

The

vetiver wetlands design: Vetiver grass were planted in rows on approximate

contour lines to spread the flood-irrigated effluent, trapping sediment,

slowing down flow velocity during storms and increasing infiltration. The

interval between rows is at about 12 metres. Temporary earth mounds were placed

behind these rows to enable the effluent to be held back so that all the young

plants receive water. Following full establishment, when the gaps between plants

are closed and the rows will take over the work of the mounds so that the earth

mounds can be removed.

Two

separate areas have been planted and each area is fed by its own pipeline

supplying effluent from the treatment ponds. This means that both areas can be

both operated at the same time, or one of them can be taken off line and dried

out so that maintenance work can be undertaken on the grass in that area. In

between the main rows of vetiver grass, extra rows were planted to increase the amount of grass in the

area.

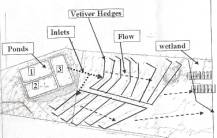

Figure

1: A general outline of the

treatment area.

Vetiver

planting density:

Planting

density of contour rows was approximately 10plants/linear metre.

Appropriate

layout design of these rows will ensure all effluent will remain in the

wetlands area during normal sunny days and during high rainfall period all

excess flow is directed toward the natural swamp at the lower end of the

treatment area.

A maintenance program will include

replacement of dead plants, regular harvest to encourage new growth. As vetiver

grass will be highly enriched with nutrient (as high as 2.4% N), the harvested

hay can be used as mulch or composting material, it is also highly palatable so

it can be used for fodder as well.

MONITORING

PROGRAM

In

conjunction with the treatment program, monitoring of both surface and

sub-surface flows is also being carried out to ensure adequate treatment and to

provide data for the site management such as quantity and frequency of

irrigation schedule during summer and winter; and wet and dry periods.

Groundwater monitoring wells are being installed at strategic points and will

be sampled on regular basis. Service water monitoring is undertaken at the

inlet to the plant, at the outlet of the Imhoff tank and lagoons, at the natural

wetlands below the Vetiver Grass wetlands and finally at the discharge into the

local creek.

IMPLEMENTATION

The wetlands were constructed over a six

month period. The work consisted of the following stages; Site Clearing, Ground

Preparation, Survey, Grass Planting,

Floating Pontoons, Operations of the wetlands and Nursery.

Site

Clearing

The

site chosen for the wetlands is on a 16.5 ha block of land to the east of the

Toogoolawah Sewerage Treatment Plant. About 8 ha of the site is being used for the

wetlands. The site was firstly cleared of all trees and bushes. Care was taken

to remove all large root systems.

Ground

Preparation

The

site was broken up into two areas with a road down the middle. An access road

was constructed around the northern side. About 60% of the areas to be planted

were prepared. Firstly the ground was sprayed with a herbicide to kill the

grass. The ground was then ploughed using a rotary hoe and then sprayed again

using Roundup.

Survey

and pipeline construction

Using

a laser level contour rows were pegged out across the slope for each area.

These rows were about 12 metres apart with a fall of 200 mm between each row.

Trenches were then dug along each row with the spoil used to form a mound on

the down hill side of the trench. The area is fed by a 150 dia pvc pipeline from the lagoon

outflow and controlled by 2 valves.

Grass

Planting

Two

types of fertilizer was placed in each row. This included DAP and Muriate of

Potash at a rate of 300 mg per hectare for both. The grass was delivered in

clumps with about fifty plants in each clump. The grass was planted along the

rows about 100 mm apart between each plant. Watering of the plants started

immediately after each day of planting. In some cases channels were dug to each

row to ensure that water got to every plant. The mounds downstream of each row

helped to get the water to every plant.

Once

the main rows were planted then further rows about 3 metres apart were also

planted. The main problem with watering was not to flood the plants for too

long. The best results were obtained when the grass was given a good watering

and then was given time to dry out. Planting started in early February and was

substantially completed by the end of March. In total about 25,000 Vetiver

Grass plants have been placed in the wetlands so far.

Floating

Pontoons

As

already described 21 floating pontoons have been placed on the treatment plant

lagoons to improve the water quality in the lagoons. Vigorous growth has been

seen in the Vetiver Grass plants that were placed onto the pontoons. The plants

are first placed in pots and then allowed to start to grow before they are

placed onto the pontoons. These

plants remove nutrients from the lagoons and so will improve water quality. To

aid in this removal of nutrients Vetiver grass was also planted around the edge

of the lagoons. About 6,000 plants have been used in the pontoons and the same

amount was planted around the lagoons.

Operations

of Wetlands

During

the planting stage the effluent was flooded onto the wetlands to enable the

grass to grow. In most of the areas the growth was good although nothing like

the growth of the grass on the floating pontoons. However when the grass was

flooded for too long a period of time say for more than two days length then the

grass didn�t grow or growth was reduced. The grass needed time in the early

stages to dry out. The normal operation of the wetlands did not commence until

early May and so the real vigorous growth cannot be expected until the next

summer.

Nursery

Because

there was not enough staff to undertake the planting quickly a small shaded

nursery was constructed on site to keep the plants alive during planting and to

produce potted plants for the floating pontoons. Whenever the operator of the

sewerage treatment plant turns on the effluent reticulation for washing the

sides of the Imhoff tank the plants in the nursery are watered automatically.

This nursery has proven to be very worthwhile and has been a great help in

enabling the project to succeed.

RESULTS OF SCHEME SO FAR

Vetiver

Grass Pontoons

Results

of a preliminary trial conducted on site with the first 3 pontoons, show that

vetiver established and flourished (up to 1.5m in 3 months) under hydroponic

conditions of all three ponds. These pontoons have been removed and the grass

harvested to produce about 5 new stems of grass from each original plant placed

on the pontoons. The pontoons have now become the source of Vetiver grass for

the project.

Growth

In The Wetlands

The

growth of the Vetiver grass has been varied for the first three months. Where

the grass was able to dry out between watering, the growth was good. In places

where the water lay around the grass the growth was poor. Some of the grass

was

planted late and so growth is not expected unto spring.

Water

Quality

There

is already evidence that the water quality is improving in respect to nutrient

loads.

Overall

an 88 per cent reduction in the nitrogen level, an 81 per cent reduction in the

phosphate level and approx 78 per cent reduction in faecal coliforms cfu\100ml

have been achieved so far